New Lower Carbon Businesses

GS Caltex is making real and substantive progress with the discovery of business opportunities in clean hydrogen clusters, establishment of an recycled composite resin production history tracking system, production of recycled products based on waste plastic, commercialization of white biotechnology, and the addition of a biodiesel plant.

White Biotechnology Business

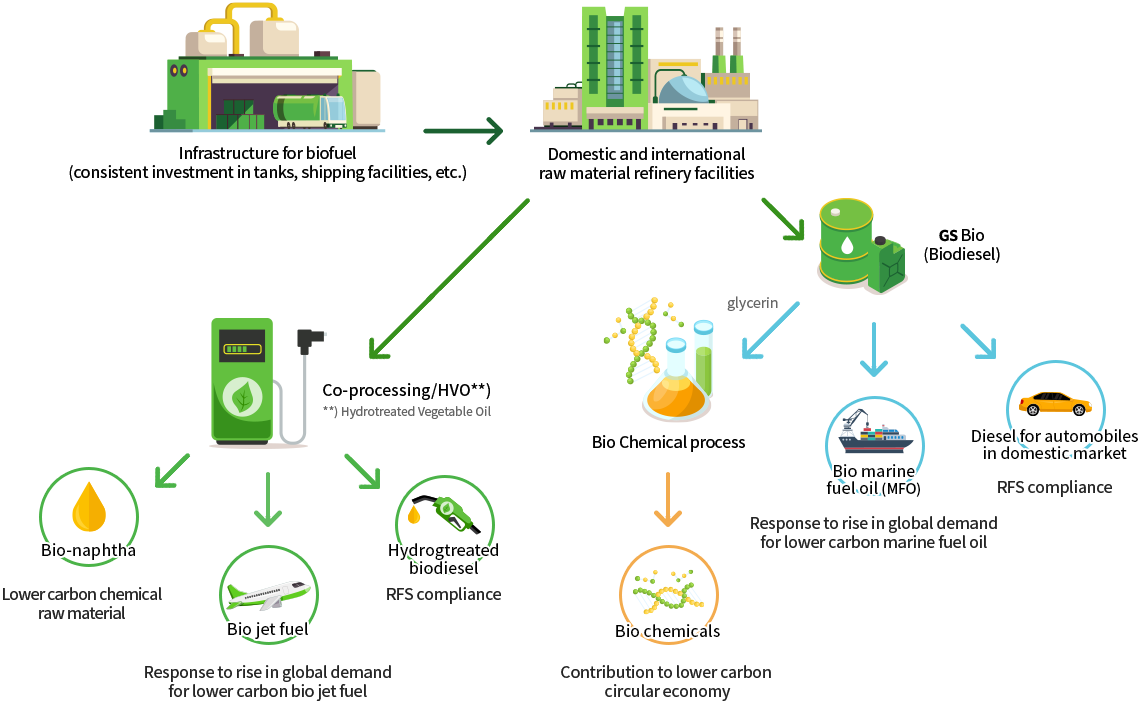

GS Caltex is contributing to the reduction of greenhouse gas by producing biofuel, biochemicals, materials, etc. derived

from sustainable biomass to replace existing products derived from fossil fuels.

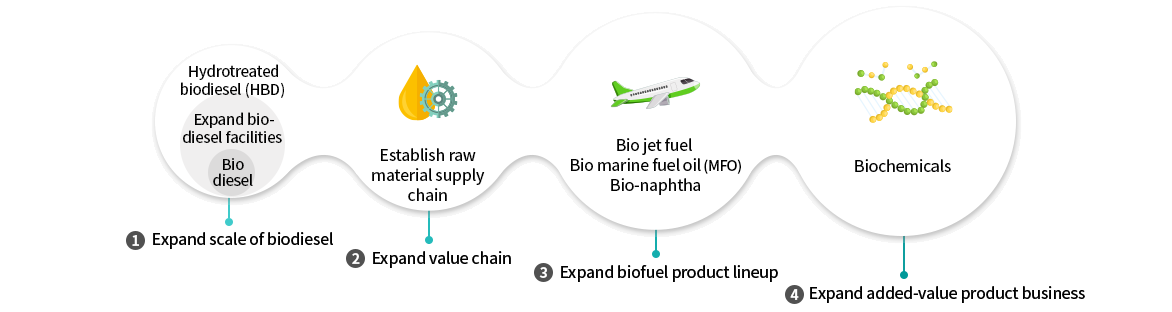

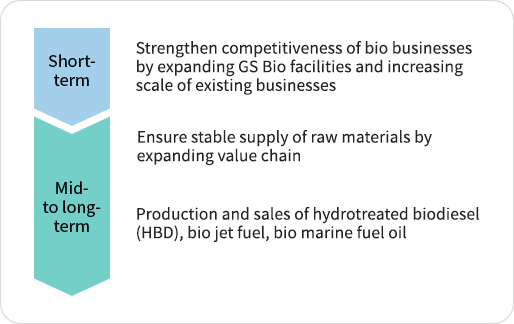

Business Strategy

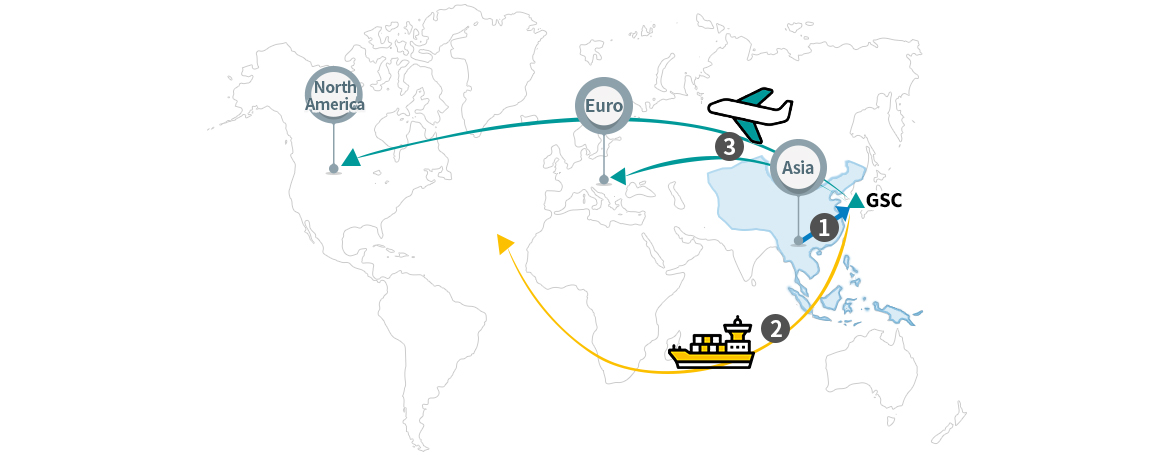

Investment Plan

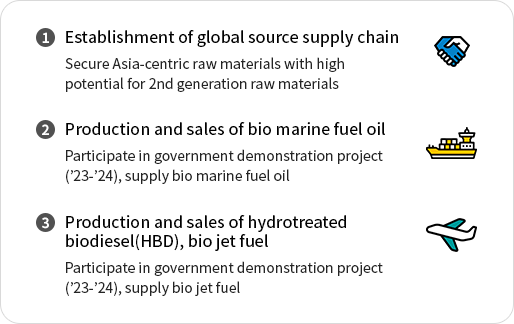

Biofuel Business

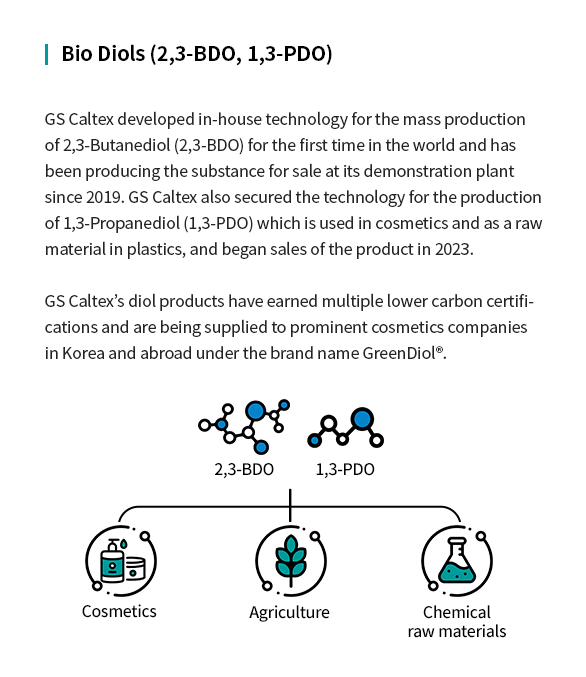

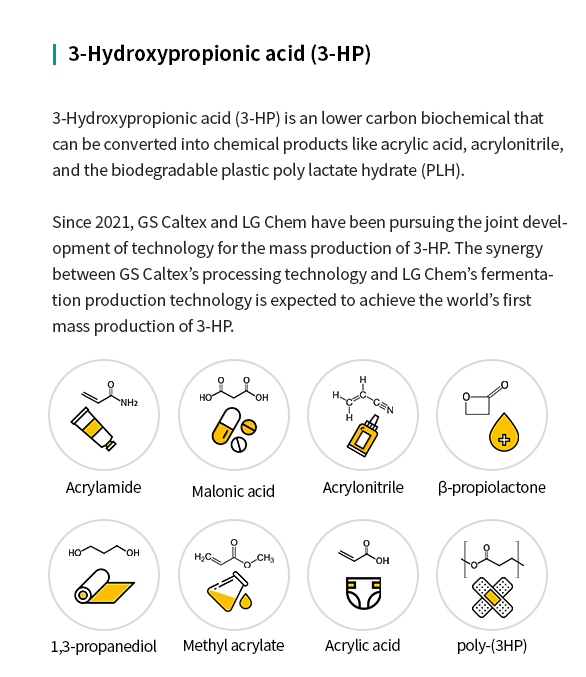

Biochemical Business

GS Caltex is growing its biochemical business by developing technologies for the lower carbon production of various biochemicals

that are used in cosmetics, agriculture, plastics, and more.

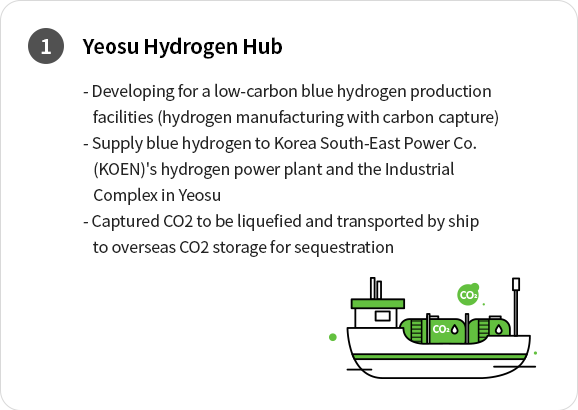

Hydrogen / Carbon Capture, Utilization and Storage (CCUS) Business

GS Caltex is expanding its hydrogen business to contribute to the supply of low-carbon energy domestically and internationally in line with global low-carbon policies, while also taking the lead in reducing greenhouse gas emissions in the industrial sector by leveraging CCUS technology.

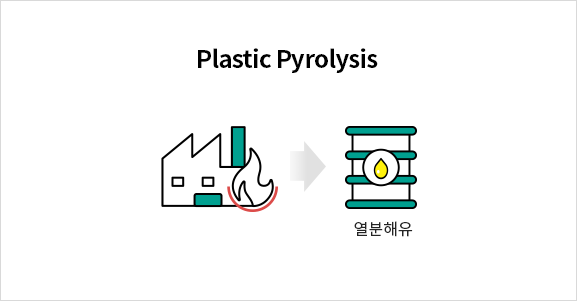

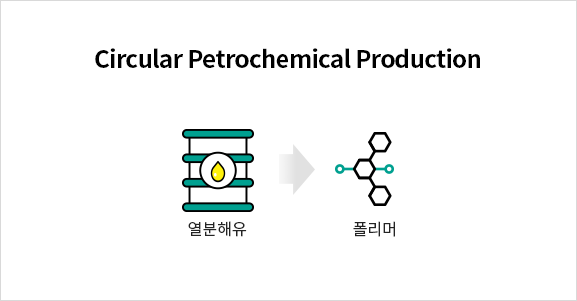

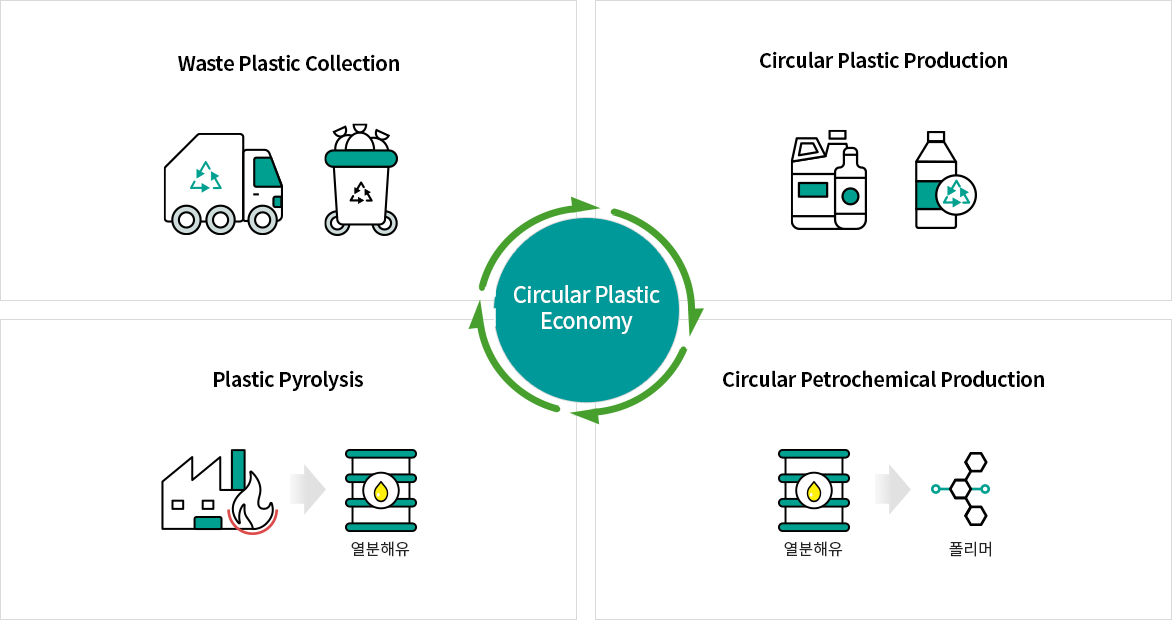

Enhancing Resource Circularity and ESG Performance through the Waste Plastic Pyrolysis Oil Business

GS Caltex is pursuing a business in chemical recycling that decomposes waste plastics to produce pyrolysis oil, which is then used as feedstock in refining and petrochemical processes to manufacture lower-carbon plastics and other products.

Since 2024, GS Caltex has been using waste plastic pyrolysis oil in its refining facilities to produce circular products, and is currently discussing with relevant partners to implement its plan to increase the volume of pyrolysis oil input.

At the same time, GS Caltex is working to diversify its pyrolysis oil sources to strengthen feedstock competitiveness by continuously engaging in various reviews and consultations.

ISCC Plus Certification

In November 2022, GS Caltex was certified for polypropylene, benzene, and ethylene under the ISCC Plus scheme. In 2024 and 2025, the certification scope was expanded to include naphtha, propylene, toluene and paraxylene, and GS Caltex plans to continuously broaden the range of certified products beyond 2025.

Third-party Validation of Life-Cycle Assessment (LCA) – Carbon Emission Reduction

The analysis showed that GS Caltex’s circular products can achieve a carbon emission reduction of approximately 150% to as much as 270% compared to conventional petroleum-based products.

Mechanical Recycling (MR) Business

Through its advanced preprocessing technology and composite resin production knowhow, GS Caltex overcame limitations in mechanical recycling

(MR) technology to become the only oil refinery company in Korea to produce recycled composite resin using waste plastic in 2010.

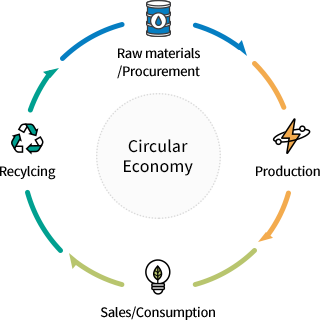

GS Caltex’s Circular Economy

GS Caltex strives to develop a sustainable circular economy that extends from procurement of raw materials to sales and consumption to resource recycling.